dry crushing process for gold

Gold Extraction Recovery Processes 911 Metallurgist

Basically the process is supported by two facts, gold is soluble in dilute solutions of cyanide, and second, the pregnant solution can be processed successfully by using zinc powder or activated carbon and electrowinning In other words, the process This page offers a comparative review of gold recovery methods: Flotation and Leaching of the Float Conc Flotation and Leaching of the sulfidefree Float Tails Gravity Gold Concentration followed by Flotation and Leaching of the Float Conc Gold Processing Methods Gold Ore ExtractionGold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulpGold Tailings Reprocessing Technology

Gold Processing,Extraction,Smelting Plant Design

Heap leaching is always the first choice to process low grade ore easy to leaching Based on the leaching test, the gold ore will be crushed to the determined particle size and then sent to the dump area If the content of clay and solid is high, to improve the leaching efficiency, the material visible during the process good recovery of gold and sulfides easy operation continuos process high capacity for small primary gold mining (50t/d for a single start spiral) no motor no moving parts Disadvantages: needs material screened to minus 2mm low enrichment factor (typical preconcentration device)Technologies for Small Scale Primary Gold Mining refractory gold is readily accessible for cyanide leaching There are several variations of comminution circuits used in the gold industry, such as: Multistage crushing and pebble and/or ball milling circuits, typical of older installations The process design of gold leaching and carboninpulp circuits by W Stange*The process design of gold leaching and carboninpulp

Full Scale Systematic Optimization Steps for a Heap Leach

Gold extraction technologies of our era have the roots for centuries Well known methods such as gravity concentration, amalgamation, cyanide leaching, zinc precipitation, and carbon adsorption are the base for todays’ technology and still used (Marsden and House, 2009) The recovery method (process selection) for gold truly Apache Mill Tailings USA, Inc is a precious metals mining company specializing in gold, silver, copper and high value, rare earth minerals reclamation recovery To maximize profits, accelerate project success and reduce risk, we work with above ground mine and ore mill tailings deposits Reclaiming Rare Earth RichesPrecious Metals Reclamation Mining Company process to recover gold59 Table 24 Estimated electricity requirements for the production of iron ore products (lumpy and fines)60 Table 25 consumed to process or produce a unit of material changes over time for a great number of reasons Estimates were developed from diverse sources that included feasibility studies,Estimates of Electricity Requirements for the Recovery of

dry crushing process for gold rebwieszollikonch

Process Of Crushing Blacksand Gold Jan 20 2019 3 put dry black sand on a sheet of clean steel 4 beat the black sand with a small hammer 5 the black sand grains shatter 6 any gold is released 7 any gold is either tiny and visible only with a x40 to x100 stereooom microscope or is big enough to be beaten flat and rendered large enough Basically the process is supported by two facts, gold is soluble in dilute solutions of cyanide, and second, the pregnant solution can be processed successfully by using zinc powder or activated carbon and electrowinning In other words, the process involves several steps from crushing Gold Extraction Recovery Processes 911 MetallurgistThe gold tailings after cyanidation are dealt with tailings dry stacking method It is a technology that recycles the filtrate to realize the water resources recycling in processing plants with pressure filtration process, and get rid of most cyanide in the tailingsGold Tailings Reprocessing Technology

Technologies for Small Scale Primary Gold Mining

tailings (for dry depositing) hand crushing hammer mill sluice box ROM (primary) concentrate to amalgamation tailings material visible during the process good recovery of gold and sulfides easy operation continuos process high capacity for small primary gold mining (50t/d for a single start spiral) By 2000 bc the process of purifying goldsilver alloys with salt to remove the silver was developed The mining of alluvial deposits and, later, lode or vein deposits required crushing prior to gold extraction, and this consumed immense amounts of manpower By ad 100, up to 40,000 slaves were employed in gold Gold processing Britannica refractory gold is readily accessible for cyanide leaching There are several variations of comminution circuits used in the gold industry, such as: Multistage crushing and pebble and/or ball milling circuits, typical of older installations The process design of gold leaching and carboninpulp circuits by W Stange*The process design of gold leaching and carboninpulp

flowsheet of crushing and grinding pdf

Gold Technology Developments and Trends ALTA Metallurgical High pressure grinding rolls are also being considered for fine crushing in gold heap leach projects in place Figure 6: Bioteq BioSulphide Process Flowsheet Read more Gold extraction technologies of our era have the roots for centuries Well known methods such as gravity concentration, amalgamation, cyanide leaching, zinc precipitation, and carbon adsorption are the base for todays’ technology and still used (Marsden and House, 2009) The recovery method (process selection) for gold trulyFull Scale Systematic Optimization Steps for a Heap Leach California miners in the 1840s used sluice boxes to siphon gold from sand or crushed rock, and hobbyist gold miners use the same process today Pulverize the rock by crushing it with a heavy mallet first, making certain to contain the bits Put the How to Test a Rock for Gold Sciencing

Precious Metals Reclamation Mining Company

Apache Mill Tailings USA, Inc is a precious metals mining company specializing in gold, silver, copper and high value, rare earth minerals reclamation recovery To maximize profits, accelerate project success and reduce risk, we work with above ground mine and ore mill tailings deposits Reclaiming Rare Earth Riches tailings (for dry depositing) hand crushing hammer mill sluice box ROM (primary) concentrate to amalgamation tailings material visible during the process good recovery of gold and sulfides easy operation continuos process high capacity for small primary gold mining (50t/d for a single start spiral) Technologies for Small Scale Primary Gold Mining Gold extraction technologies of our era have the roots for centuries Well known methods such as gravity concentration, amalgamation, cyanide leaching, zinc precipitation, and carbon adsorption are the base for todays’ technology and still used (Marsden and House, 2009) The recovery method (process selection) for gold trulyFull Scale Systematic Optimization Steps for a Heap Leach

The process design of gold leaching and carboninpulp

refractory gold is readily accessible for cyanide leaching There are several variations of comminution circuits used in the gold industry, such as: Multistage crushing and pebble and/or ball milling circuits, typical of older installations The process design of gold leaching and carboninpulp circuits by W Stange*A New Age Gold Plant Flowsheet for the Treatment of High Gekko The circuit incorporates crushing and coarse grinding (often plus The flowsheet described in this paper has been developed in flowsheet of crushing and grinding pdf Crushing plant product is then conveyed 14 kilometres to fill any one of six fine ore bins, each one feeding six rod mill flotation sections, all operating in parallel Certain sections are used for wet grinding marginal ore to below 03mm, followed by a copper flotation process Palabora Mining Company Ltd

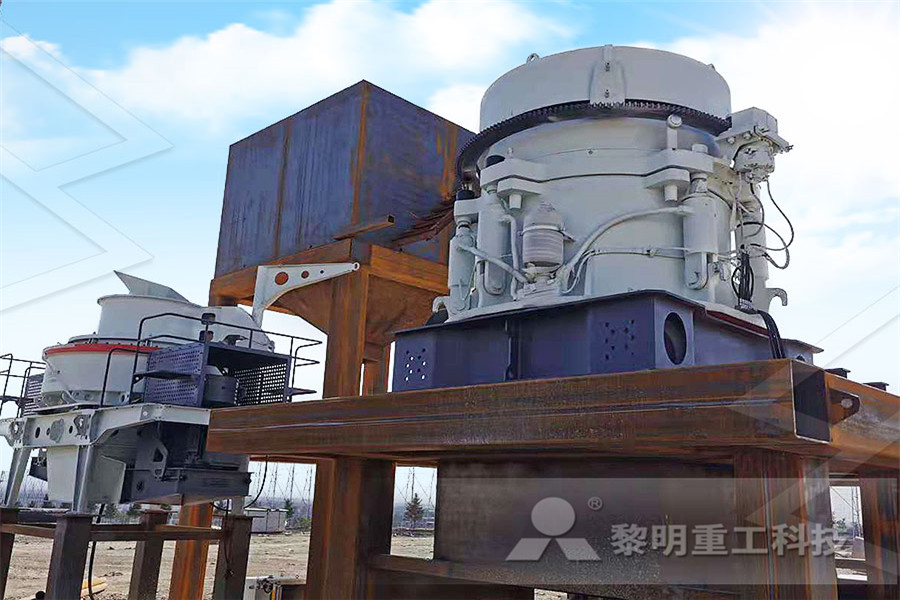

Crusher an overview ScienceDirect Topics

Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers 13311 Primary CrusherBoth open and closed circuit crushing is employed For close circuit the product is screened with a mesh size much less than the set Figure 64 is a typical setup where ores crushed in primary and secondary crushers are further reduced in size by a rough roll crusher in an open circuit followed by finer size reduction in a closed circuit by a Primary Crusher an overview ScienceDirect Topics By 2000 bc the process of purifying goldsilver alloys with salt to remove the silver was developed The mining of alluvial deposits and, later, lode or vein deposits required crushing prior to gold extraction, and this consumed immense amounts of manpower By ad 100, up to 40,000 slaves were employed in gold Gold processing Britannica

New dry iron ore processing technology developed

Brazilian company New Steel have developed a new dry iron ore tailings process to make mining more environmentally sustainable It involves the dry Solutions Cement Production Line Cement production line is also known as the dry type cement production line, with high productivity and high degree of automation; Stone Production Line Stone production line is the sand production line, special for crushing gravel and stoneJaw Crusher/Impact Crusher/Crusher/Hammer