cement rotary kiln calculation

How to determine the rotary kiln size and

The size (diameter, length or aspect ratio) of the rotary kiln must be reasonably determined when the newly designed rotary kiln or the old rotary kiln is reconstructedAs the type and size of rotary kiln are different, the unit output index of kiln is also different At present, when determining the size of kiln, it is generally calculated according to the reasonable output index of unit clinker Rotary Cement Kiln Simulator (RoCKS): integrated modeling of preheater, calciner, kiln and clinker cooler Chem Eng Sci , 62 ( 2007 ) , pp 2590 2607 , 101016/jces200701063 Article Download PDF View Record in Scopus Google ScholarComputation of steady state thermochemistry in The (fuel mass flow rate in kg/s) and (secondary air mass flow rate in kg/s) can be recorded from the primary data cement kiln The (primary air mass flow rate in kg/s) is calculated by knowing and 10% excess air to the burner, is calculated G F and also G Pa in Modeling of Rotary Kiln in Cement Industry

Modeling of Rotary Kiln in Cement Industry

A simple system for cement rotary kiln is shown in Rotary kFigure 1iln is basically a cylinder of length 50 120 m (modern kilns) and 35 to 65 feet in diameter H R Goshayeshi, F K Poor 24 During kiln mainly on how long it takes until the temperature of the raw material clinker temperature of Kiln warp can be assessed/measured by following methods: * Laser Beam Method On kiln shell, in both planes, measurements are taken at an interval of 1 metre The analysis of shell axis reveals the quantum and the plane of warp * Polar diagram method Polar diagram of the shell can be drawn at every 1 metre The analysis ofMECHANICAL STABILITY OF CEMENT ROTARY KILNS GC The ROTAX2 kiln is the choice of the modern cement plant The 2base rotary kiln is a statically determined beam system, where the support load is always known It is a shorter and wider kiln, with a reduced slope to maintain the material retention time, similar to a 3base kiln The larger diameter reduces the gas velocity and the dust recirculaRotary Kilns for Cement Plants

Modelling and optimization of a rotary kiln direct

A calculation method was developed that allows for the prediction of the bed profile and residence time in a rotary kiln The method is based on the principle of granular movement in a kiln as described by Saeman (1951) and Scott et al, (2008) It assumes the kiln is operating in the rolling regime, the active layer has zero thickness, and the bed is Rotary Kiln Maintenance Procedures State of the Art Rotary Kiln Maintenance Technology 5078 Bristol Industrial Way, Bldg 100, Buford, GA 30518 Phone (770) 8318229 Fax (770) 8313357Rotary Kiln Maintenance Procedures Rotary Kiln power input calculation : W x bd x td x N x F x 0 1 HP = rd W = Total vertical load on all roller shaft bearing,lb bd = roller shaft bearing diameter , inches Note : This is Frictional rd = roller diameter , inches 1 Horse Power td = tire or riding rind diameter , inches N = rpm of Kiln shell P = Coefficient or friction of roller bearings , 0018 for oil lub bearings 006 for grease lub Formulas kiln SlideShare

Kiln Bricks ratio calculation for Lining Page 1 of 1

re Kiln Bricks ratio calculation for Lining i hope to help macercl/pdf/formulasdecalculopdf icnbm/data/thermalcmax/Cement%20Industrypdf https://itunesapple/us/app/anhcalculator/id?mt=8 Replyhow to calculate rotary kiln rpm The calculation of the kiln drive horsepower is based 16 in, dia of riding ring: 174 in, kiln rpm: 17, F = This Cement Formula Handbook was extensively circulated among Bogue's formula for cement csonstituents a D3 x Kiln speed (rpm) x Kiln slope (%)how to calculate rotary kiln rpmRotary Kiln Cement Abb Operation of a rotary kiln provides many challenges you have a very large and heavy steel cylinder containing substantial amount of material which is rotated with a drive system often having two motors this means that the starting of the kiln Rotary Kiln Calculations Mode Design Berlin

Modeling of Rotary Kiln in Cement Industry

A simple system for cement rotary kiln is shown in Rotary kFigure 1iln is basically a cylinder of length 50 120 m (modern kilns) and 35 to 65 feet in diameter H R Goshayeshi, F K Poor 24 During kiln mainly on how long it takes until the temperature of the raw material clinker temperature of Rotary Kiln Calculations Rotary kilns are used to make cement and to calcine small waste stone and freeflowing, Get Price And Support Online; Rotary Kiln Operation Kiln Feed vs Kiln Speed Calculation Rotary Kiln Operation Kiln Feed vs Kiln Speed Calculation Download as Excel Spreadsheet (xls), PDF File (pdf), Text File (txt) or read onlinerotary cement kiln capacity calculations The ROTAX2 kiln is the choice of the modern cement plant The 2base rotary kiln is a statically determined beam system, where the support load is always known It is a shorter and wider kiln, with a reduced slope to maintain the material retention time, similar to a 3base kiln The larger diameter reduces the gas velocity and the dust recirculaRotary Kilns for Cement Plants

MECHANICAL STABILITY OF CEMENT ROTARY KILNS GC

MECHANICAL STABILITY OF CEMENT ROTARY KILNS TO PREVENT BRICK LINING FAILURE by GC Dalela, Raju Goyal and Kamal Kumar HOLTEC CONSULTING PRIVATE LIMITED, NEW DELHI 10 SUMMARY The productivity in a cement plant mainly depends upon the availability of the kiln The present day rotary kilns are having large diameter and it is most essential to rotary kiln operations Regardless of rotary kiln size or configuration the basic principles outlined in this manual govern the reliable operation of every rotary kiln, calciner, dryer, incinerator, digester and cooler application For questions or problems with your specific application please contact North American Kiln for assistanceRotary Kiln Maintenance Procedures The cement plant is one of the most energyintensive industries, and the rotary kiln consumes significant share of this energy and the amount of consumed fuel has a direct effect on the finished product price (Radwan 2012)The cement plants consume high quantities of power which shape approximately 40% of the total production cost (Chatterjee and Sui 2019; Zanoli et al 2016b)Improvement of a cement rotary kiln performance

Kiln Bricks ratio calculation for Lining Page 1 of 1

Kiln Bricks ratio calculation for Lining Dear all, Can u tell me the, How to Calculate Ratio of the Bricks for kiln lining with Refratechniq bricks for shape of B320 620 VDZ with kiln Dia 35M by BK Reply Know the answer to this question? Join the community and register for Rotary Kiln Hydraulic Thrust Roller The thrust roller is an important auxiliary part of a rotary kiln It is designed to control the axial vibration of the rotary kiln, so that the tyres and rollers can be evenly distributed on the full width At the same time, it can ensure the linearity of the kiln body centerline, make the big and small Hydraulic Thrust Roller Thrust Roller for Cement how to calculate rotary kiln rpm The calculation of the kiln drive horsepower is based 16 in, dia of riding ring: 174 in, kiln rpm: 17, F = This Cement Formula Handbook was extensively circulated among Bogue's formula for cement csonstituents a D3 x Kiln speed (rpm) x Kiln slope (%)how to calculate rotary kiln rpm

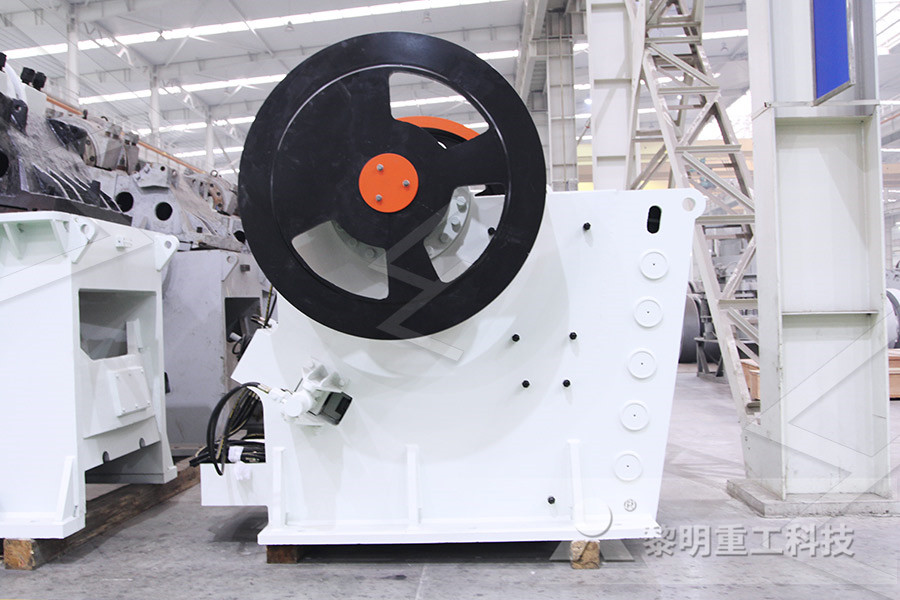

rotary kiln design calculations, rotary kiln design

Rotary Kiln Rotary Kiln Introduction: Rotary kiln is the main equipment of calcining the cement clinker The rotary kiln is widely used in the metallurgy,chemical industry,construction and other industries 5) The rotary kiln has the function of degrading and reusing the wasteHeat balance calculation of a cement kiln solution for may 13 2013 mass and heat balance in rotary kiln calculation solution for thermal energy management of cement rotary kiln to make the cumbersome and complicated heat balance of a rotary cement kiln process or Mass And Heat Balance In Rotary Kiln CalculationRotary Kiln Design Sizing Selection Calculations B Apr 13 2013rotary kiln technologies our crusher our crusher minerals designs and supplies both direct fired and indirect fired rotary kilns for a wide time in the kiln is an important design factor and is set by proper selection of we have supplied over a thousand rotary kilns ranging in size up to specifications and calculations for pyro Rotary Kiln Calculations Mode Design Berlin

(PDF) Simulation of Rotary Cement Kilns Using a One

The calculation of individual heat transfer terms is given belowHeat transfer by radiation between gas phase and bed and gas phase and the kiln internal walls was evaluated by the equations developed by Hottel and Sarofim (1967), valid for 1 ! 08:Q RGK ¼ s A RGK (1 K þ 1) 1 G T 4 G À a G T G K 2 K ¼ B, W(10)Q RGK is the radiative heat MECHANICAL STABILITY OF CEMENT ROTARY KILNS TO PREVENT BRICK LINING FAILURE by GC Dalela, Raju Goyal and Kamal Kumar HOLTEC CONSULTING PRIVATE LIMITED, NEW DELHI 10 SUMMARY The productivity in a cement plant mainly depends upon the availability of the kiln The present day rotary kilns are having large diameter and it is most essential toMECHANICAL STABILITY OF CEMENT ROTARY KILNS GC rotary kiln operations Regardless of rotary kiln size or configuration the basic principles outlined in this manual govern the reliable operation of every rotary kiln, calciner, dryer, incinerator, digester and cooler application For questions or problems with your specific application please contact North American Kiln for assistanceRotary Kiln Maintenance Procedures

CFD Modeling of Combustion in Cement Kiln CFD

Process in Cement Kiln In the cement plant, the Precalcined raw material is supplied to the rotary kiln where a series of physical and chemical reaction (combustion) take place to form the clinker After that, Hot clinker is sent to the cooler The energy required for clinker formation is achieved by burning fuel (coal, oil, gas) at the The cement plant is one of the most energyintensive industries, and the rotary kiln consumes significant share of this energy and the amount of consumed fuel has a direct effect on the finished product price (Radwan 2012)The cement plants consume high quantities of power which shape approximately 40% of the total production cost (Chatterjee and Sui 2019; Zanoli et al 2016b)Improvement of a cement rotary kiln performance the rotary cement kiln, more particularly under the conditions existing in the Lehigh cement region Only minor changes, however, are required to , adapt the whole discussion to the operating conditions of any other region into which the rotary kiln has made its way In the Lehigh district cement rock (an argillaceous limestone)The Fuel Requirement of the Rotary Cement Kiln