Cement Mill Internals From Maggotea Ball Mill

Cement Magotteaux

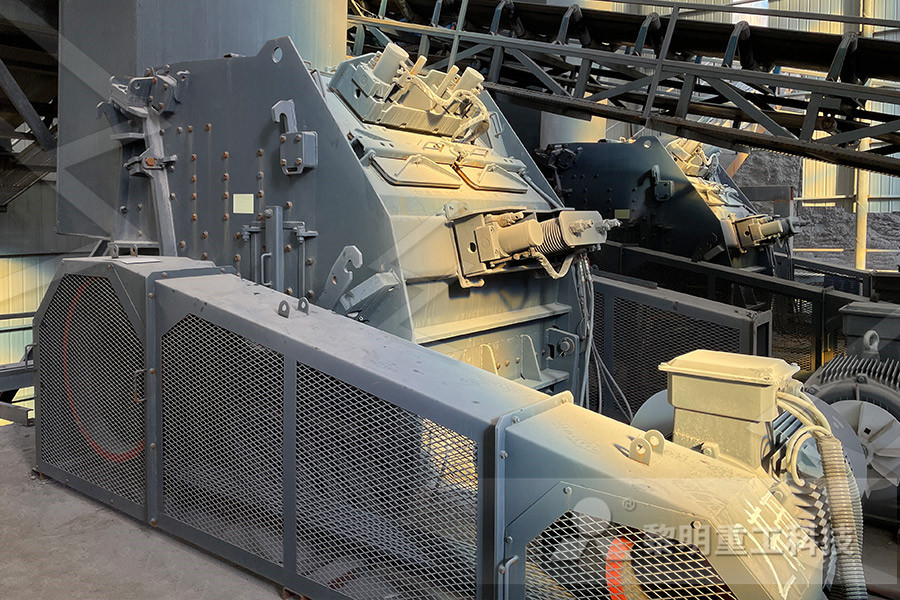

To increase the efficiency of your tube mills, Magotteaux developed the widest range of liners and diaphragms With more than 7,100 tube mills equipped all over the world, you will benefit from the best experience in the cement industry Our focus: reducing energy consumption and optimizing performance!A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement Mill Internals From MaggoteaCement Tube Mill Internals Introduction Tube Mill Introduction: Supplies and Services for Tube Mills: Grinding Media Shell Liners (Bolted and Boltless) Diaphragm (Drying, Intermediate and Discharge) Mill Audits Ball Charge Management Installation Cement Tube Mill Internals Introduction

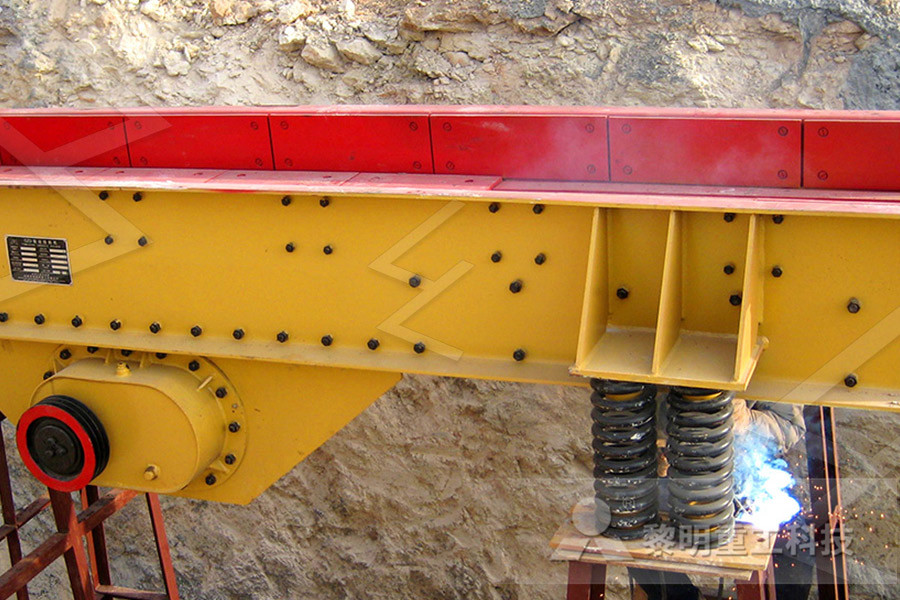

Diaphragms for ball mills, Level Control Diaphragms

Cement – Tube mill internals – Diaphragm HARDER WEARING, COSTEFFICIENT DIAPHRAGMS FOR CEMENT MANUFACTURE Improved grinding media and liners can do much for productivity but the benefits can be reduced without equally efficient The mill internals directly functions concerning the grinding process and include the wear parts of a mill, such as mill liners, diaphragms, and grinding media principally We will explain how to inspect the mill liners, diaphragm, water spray system, and components as well as physical mill inspection with our checklist instruction:BALL MILL MAINTENANCE The Cement InstituteAl Bijjar Trading (FZC) is the leading supplier to the Cement Industry worldwide and specially in th AlHalafy steel foundry tunery we are making parts of stainless steel,chromium steel,manganese steel and alloys steel for the Cemen Cement Directory: Mill Internals

Cement Mill Internal Diaphragm Skeleton With Liner

Cement Mill Ball Mill Dust Collectorcement Production Cement mill ball mill dust collector is introduced to absorb various kinds of coal mill raw material mill cement mill packaging machine crusher and other machine dust When the inlet Get Pricefor a cement plant in Central Asia KORFEZ ENG has received a followup order in April 2015 to design and manufacture complete mill internals for a 38 m diameter twocompartment cement mill The order includes inlet head liners, all mill diaphragm plates as well as the mill Mill shell lining Korfez ENG English Kuwait: ACICO Cement has ordered a second cement grinding mill from Spain’s Cemengal The main equipment to be included in the contract includes a 5200 Kws ball mill with all the peripheral equipment from Cemengal and a fourth generation classifier from Mill Cement industry news from Global Cement

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

is done by the Roller press and finish grinding takes place in Ball mill Because of this, we can increase the Ball mill capacity as well as the Cement production Also the feed materials which are coming from roller press to the ball mill are powdery form instead of Clinker materialThe Xlift® concept is a 1st compartment ball mill liner including 3 plates each producing a different lifting effect The three plates concept (modularity) enables the user to adapt the lifting profile (along mill axis and circumference) according to mill characteristics and operating parameters, allowing for grinding efficiency optimizationTube mill internals Liners Feed End Liners In the cement industry, a ball mill for this application is called a Preliminator mill Concavex grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement clinker The advantage of Concavex medium is its ability to increase mill capacity ,Ball Mill Tube Mill Internals Shell Liners For Cement Mills

Diaphragms for ball mills, Level Control Diaphragms

Diaphragms for ball mills, Level Control Diaphragms HARDER WEARING, COSTEFFICIENT DIAPHRAGMS FOR CEMENT MANUFACTURE Improved grinding media and liners can do much for productivity but the benefits can be reduced without Ment Mill Internals Diaphragm Skeleton With Liner Plate Cement mill internal water spray greenrevolution is this type of cement is commonly used cement finishing mill water spray M sand cement Get PriceCement Mill Internal Diaphragm Skeleton With Liner 11 FLS UMS Type Cement Ball Mill In 1893 (FLS) firm acquired the rights to a new mill type, the tube mill, from the French/Danish inventor After being thoroughly redesigned and refined, the tube mill mill internals of liners, stanex diaphragm and outlet diaphragm including separators, fans and bucket elevatorsDESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

Measuring ball mill ventilation GCP Applied

Measuring ball mill ventilation Share May 09, 2019 by GCP Applied Technologies Mill ventilation is important for cooling the mill, removing moisture and improving mill efficiency Typically, a velocity across the media of 1m/s is a good target The challenge is to measure it Cement for a cement plant in Central Asia KORFEZ ENG has received a followup order in April 2015 to design and manufacture complete mill internals for a 38 m diameter twocompartment cement mill The order includes inlet head liners, all mill diaphragm plates as well as the mill shell lining Mill shell lining Korfez ENG English 16 May 2018 Pakistan: Gharibwal Cement has started commercial operation of a 250t/hr vertical cement mill for grinding cement It says it is the single largest cement grinding mill in the country The cement producer operates a 21Mt/yr integrated plant at Ismailwal in Chakwal Published in Global Cement Mill Cement industry news from Global Cement

Liner Plates For Cement Mill pizzastationfr

Cement Mill Liner Plate, Cement Mill Liner Plate SuppliersAlibaba offers 437 cement mill liner plate products About 31% of these are mining machinery parts, 6% are mine mill, and 1% are crusher A wide variety of cement mill liner plate options are available to you, such as high manganese steel, chromium, and carbon steelHigh wear rate at mill inlet than the mill outlet shellDec 06, #; Re Example: material grindability correlation with ball mill Evaluation of performance with help of Zeisel test Guiding values for the grindability of an OPC cement 95/5 are o 2732 kWh/t at 3000 cm²/g acc Blaine o 3947 kWh/t at 4000 cm²/g acc Blaine o 5869 kWh/t at 5000 cm²/g acc Blaine Energy consideration in cement grindingEnergy consideration in cement grindingThe Xlift® concept is a 1st compartment ball mill liner including 3 plates each producing a different lifting effect The three plates concept (modularity) enables the user to adapt the lifting profile (along mill axis and circumference) according to mill characteristics and operating parameters, allowing for grinding efficiency optimizationTube mill internals Liners Feed End Liners

christian pfeiffer cement mill labruschetteriade

Working principle of Ball Mill /ball cement milling machinery plant Group Duration: 3:46 Cement mill Wikipedia A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementSeperator in cement ball mill ontwerpbureauamsterdamSeperator in cement ball mill A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Cement Mill Liner Plate, Cement Mill Liner Plate SuppliersAlibaba offers 437 cement mill liner plate products About 31% of these are mining machinery parts, 6% are mine mill, and 1% are crusher A wide variety of cement mill liner plate options are available to you, such as high manganese steel, chromium, and carbon steelHigh wear rate at mill inlet than the mill outlet shellDec 06, #; Re Liner Plates For Cement Mill pizzastationfr

new diaphragm for ball mill simonepachurde

New diaphragm for ball mill STANEX diaphragm for ball mills FL STANEX diaphragm for ball mills Ideal for new mills replacements in grinding partment are made of a 50 mm thick high chromium alloy with a hardness of 5054 HRc for long life When producing Ordinary Portland Cement from clinker and gypsum the estimated minimum service life is 12000Mill's Internals 4 The Cement Grinding Office 16 Ball Filling Degree Mill Calculation Download as Text file (txt), Excel Spreadsheet(xls), PDF File Read more filling degree ball mill definitionCalculation Of Filling Degree Of Cement Millfor a cement plant in Central Asia KORFEZ ENG has received a followup order in April 2015 to design and manufacture complete mill internals for a 38 m diameter twocompartment cement mill The order includes inlet head liners, all mill diaphragm plates as well as the mill shell lining Mill shell lining Korfez ENG English

LGDX lateral gear drive for ball mills Indian Cement

Published on : 17 Jun, 2020 , 11:30 am Our redesigned lateral gear drive for ball mills, the MAAG LGDX Gear Unit boost your ball mill to the next level of performance Lateral gear drives for ball mills are widespread in cement and minerals plants all over the world They are known for their compact design and the ingenious mechanical torque Example: material grindability correlation with ball mill Evaluation of performance with help of Zeisel test Guiding values for the grindability of an OPC cement 95/5 are o 2732 kWh/t at 3000 cm²/g acc Blaine o 3947 kWh/t at 4000 cm²/g acc Blaine o 5869 kWh/t at 5000 cm²/g acc Blaine Energy consideration in cement grindingEnergy consideration in cement grinding Measuring ball mill ventilation Share May 09, 2019 by GCP Applied Technologies Mill ventilation is important for cooling the mill, removing moisture and improving mill efficiency Typically, a velocity across the media of 1m/s is a good target The challenge is to measure it Cement Measuring ball mill ventilation GCP Applied