pelletizing plants mineral

World´s first Circular Pelletizing Plant from Primetals

The CPT plant is located amidst mineral rich BarbilBarajamada belt in the State of Odisha The pelletizing plant´s active induration furnace area amounts to 191 m2 Primetals Technologies scope of supplies and services included the design of the induration furnace and the design of the preprocess facilities, like additive grinding, mixing and green pelletizing, as well as advisory and startup services Outotec has signed a contract with Beijing Shougang International Engineering Technology Co, Ltd (BSIET) on the delivery of environmentally sound pelletizing technology for Yunnan Yuxi Yukun Iron and Steel Group Co, Ltd The iron ore pelletizing plant will be built in the Dahua industry park of Eshan, Yuxi, Yunnan/ChinaPelletizing plant order in China Mineral Processing In October, the world´s most compact pelletizing plant was startedup at the Basantpur, Keonjhar district site of Pro Minerals Pvt Ltd (Pro Minerals) in the Indian State of Odisha The plant was supplied by Primetals Technologies and applies Circular Pelletizing Technology (CPT) The plant is World´s first Circular Pelletizing Plant from Primetals

Mars Mineral Agitation Agglomeration Equipment

Mars Mineral Corporation furnishes pelletizing equipment, engineered systems, turnkey plants and services for a wide range of dust and powder agglomeration Equipment may include pin agglomerators and disc pelletizers or deep drum pelletizers Pelletizing is defined as an agglomeration process whereby an amorphous mass of finely divided Various industries rely on pelletizing plants to process bulk solid materials ranging from specialty chemicals and fertilizers, to additives and mineral products Despite its pervasive use, however, the pelletizing process can be challenging to optimize, particularly for operations that employ a pin mixerdisc pelletizer Pelletizing Plant Optimization: Conducting a Process Pelleted manure may have mineralization characteristics differing from those of its raw components due to the high temperatures and pressure involved in the pelleting process The rate of N mineralization of raw manures and pelleted manure was studied in water and in soil incubation experimentsEffect of Pelleting, Temperature, and Soil Type on

to acquire iron ore pelletizing technology

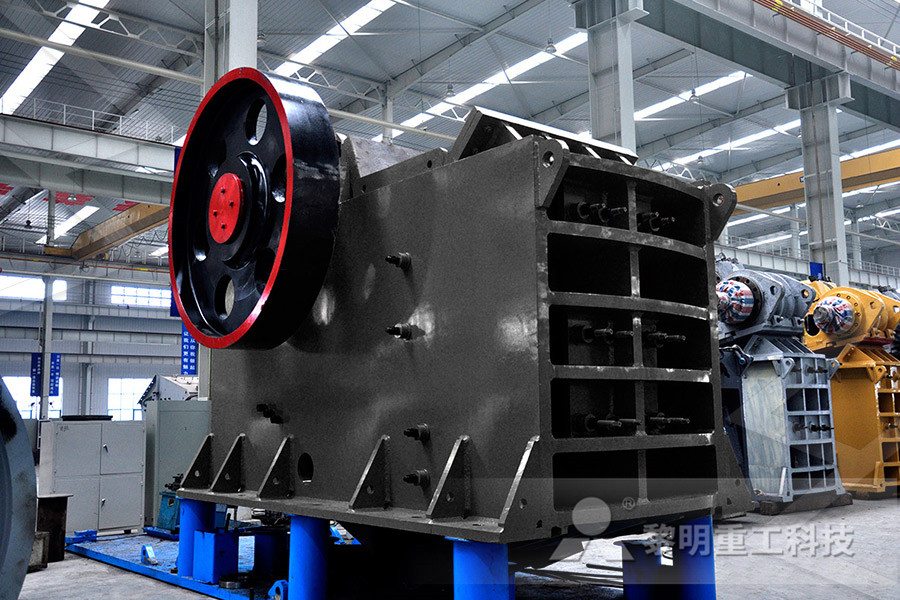

anticipates continued growth in this market as more beneficiation and pelletizing plants are needed to maximize the output from lower grade ore bodies currently offers the Grate Kiln Iron Ore Pelletizing system With the purchase of the Straight Grate Technology from Jacobs, will be able to offer both systemsOur most popular works Primary, secondary screening and crushing plants for minerals Up to 2000 T/H and 1800 MM EDGE LENGTH, Washing and pelletizing Plants Screening for building materials Scalper up to 2000 T/H 1800 MM EDGE LENGTH; Classify Screening up to 1200 T/H up to 300 grain size; Fine Screening 10 T/H 300 T/H; 100 MM 5 MM Haver Niagara – Your competent partner in mineral The pelletization process is very widely used, particularly when burden materials must be shipped great distances between the mine and the blast furnace, because fired pellets are durable and easy to handle Pellets also perform very well in the blast furnace, with Iron ore pelletization ScienceDirect

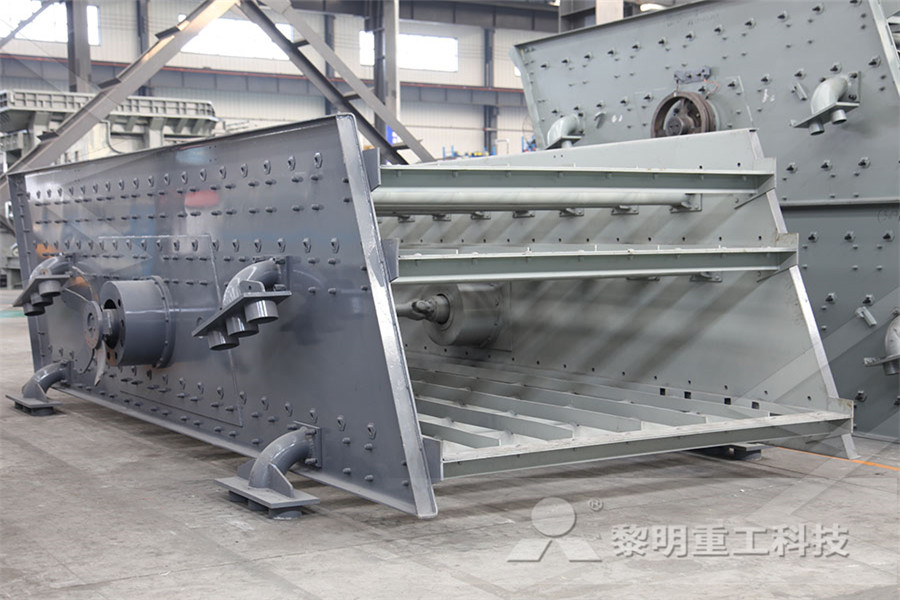

Conveyor systems for pelletizing plantsHenan Mining

2 Iron ore pelletizing GrateKilnTM iron ore pelletizing system The first GrateKilnTM system pellet plant was installed in 1960 The plant took iron ore concentrate and produced superior iron ore pellets (which are spheres of Downdraft drying Downdraft drying Preheat zone Rotary kiln Zone 1 Zone 2 Zone 3 Zone 4 Pellets Stack Travelling grateLKAB has six pelletizing plants: three in Kiruna, two in Malmberget and one in Svappavaara The total capacity of the plants amounts to approximately 28 million tonnes of processed iron ore products per year The pellets are formed In the pelletizing plant, a clay mineral, bentonite, is added as a binder in the iron ore concentratePelletizing LKAB Outotec has signed a contract with Beijing Shougang International Engineering Technology Co, Ltd (BSIET) on the delivery of environmentally sound pelletizing technology for Yunnan Yuxi Yukun Iron and Steel Group Co, Ltd The iron ore pelletizing plant will be built in the Dahua industry park of Eshan, Yuxi, Yunnan/ChinaPelletizing plant order in China Mineral Processing

Iron ore pelletizing Outotec

Outotec pelletizing plants have a faster start up and better reliability than other plants in the industry Iron ore can be upgraded to a higher iron ore content through beneficiation This process generates iron ore filter cake which needs to be pelletized Pellet Mill Our KAHL pellet mills facilitate storage and transport of your bulk products and product mixtures Particularly fineparticle or dusty products are often a challenge when it comes to storage Both the porosity and the volume require special measures – also during transport Our KAHL pellet mills help you to save operating Pellet Mills Pelleting PlantsConveyor systems for pelletizing plants Mars Mineral engineers, manufactures and pelletizing systems to convert poultry manure into See more details Pelletizing System USEON A simple water bath for strand cooling often is the first option for compounding plants This system is only for mediumsmall production size This system consists of Conveyor systems for pelletizing plantsHenan Mining

Our Products : Ground Force Pelletized Lime

Our pelletizing procedure grants an even spread of our product to ensure that both magnesium and calcium are distributed evenly throughout the soil Helps with the photosynthesis process in plants Supplies Magnesium to acidic soil Improves the microbial action to help break down pesticides and organic matter Before switching to magnetite pelletizing, Arrium Mining in South Australia ballmilled hematite/goethite fines for pelletizing Similar procedures are currently used in some pelletizing plants in India as well, especially in Tata Steel's 6 Mtpa straight grate pellet plant, which is the first in the world to use dry grinding to achieve specific Iron ore pelletization ScienceDirectLocation of Circular Pelletizing Plant not necessarily at mine site, but also at steel works or direct reduction plants Induration furnaces for capacities between 08 and 30 mt/a considered Production of high quality Blast Furnace and Direct Reduction grade pellets as well as Manganese pellets Circular Pelletizing TechnologyPELLETISATION Metal Bulletin

Pelletizing FEECO

Pelletizing is a particle size enlargement (agglomeration) technique frequently used to transform the handling and performance characteristics of bulk solids Pelletizing can be used to eliminate dust, control active ingredient release properties, improve application, and more1 2 ton/hr For making briquettes of charcoal, coal dust, carbon dust, coke dust, clay and other mineral dust or waste $8,12500 Read More Pellet Mill Flat Die MKFD300AUSA Pellet MillIron Ore Pelletizing Cement Mineral Processing Industries like Iron Ore Pelletization and Lime Industry Sarvesh undertakes total refractory management in large steel plants and has successfully executed management contracts across all major areas of SteelmakingIron Ore Pelletizing Sarvesh

Pellet Mills Pelleting Plants

Pellet Mill Our KAHL pellet mills facilitate storage and transport of your bulk products and product mixtures Particularly fineparticle or dusty products are often a challenge when it comes to storage Both the porosity and the volume require special measures – also during transport Our KAHL pellet mills help you to save operating Manufacturer of standard and custom pelletizers and pelletizing equipment and plants Disc pelletizers are available Features include greased pan bearings, pan inclination, manually or motor actuated pan tilt mechanism, pan floor cleaned by rotating scrapers, wall and rim scrapers with tungsten carbide platelets and pan equipped with dust hood and exhaust connectionsPelletizers Pelletizing Equipment PlantsOre handling, beneficiation and mineral dressing from crushing, milling and flotation for Bulk material handling systems; Slurry pipelines with the entire necessary infrastructure; Pelletizing plants and facilities; Achievement: Upgraded; Iron Ore (Hematite): 43% to Mineral Processing Plants Iron Ore Processing Plant

Haver Niagara – Your competent partner in mineral

Our most popular works Primary, secondary screening and crushing plants for minerals Up to 2000 T/H and 1800 MM EDGE LENGTH, Washing and pelletizing Plants Screening for building materials Scalper up to 2000 T/H 1800 MM EDGE LENGTH; Classify Screening up to 1200 T/H up to 300 grain size; Fine Screening 10 T/H 300 T/H; 100 MM 5 MM The total capacity in LKAB's six pelletizing plants amounts to around 28 million tonnes of processed iron ore products per year The iron ore is processed to two main types of products: blast furnace and direct reduction pellets (DR pellets) You can read more about our iron ore products hereProcessing LKAB Most pelletizing plants are situated near the mine and obtain their ore from the concentrator The ore is delivered as a slurry and consequently grinding is performed wet After grinding the slurry is pumped to vacuum filters where the water is removed Pelletizing Ore Mixtures 911 Metallurgist

Iron Ore Pelletizing Process: An Overview

Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2 Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processing Often concentrates are produced from mineral processing plants in fine particulate form and as such Both the continuous sintering and pelletizing process yield a satisfactory product It is also possible to maintain high plant availability and to scale up the units to a XI AGGLOMERATION Iron ore pelletizing process The iron ore pelletizing process is comprised of three main stages: (1) raw material preparation, (2) green pellets production and (3) thermal treatment of green pellets Pelletizing plants usually receive concentrated ore sludge from the mining siteBiomass gasification for natural gas substitution in