flash flotation process in chemistry

Flash flotation and the plight of the coarse particle

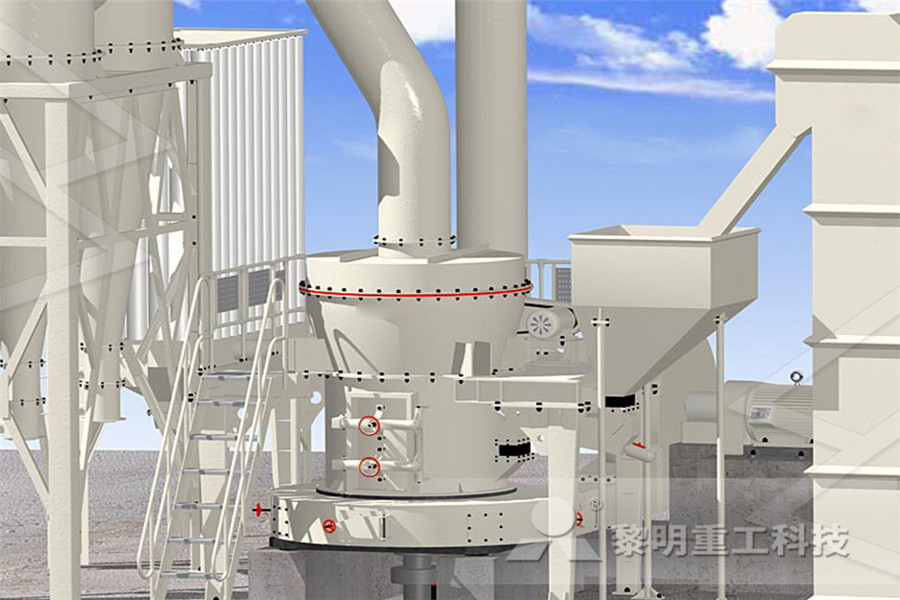

Introduction From the perspective of a plant metallurgist or operator, the role of a flash flotation cell in a concentrator is to remove any liberated valuable mineral and/or any coarse composite particles rich in the target valuable mineral; and this has also been the long held belief of the authors Flash Flotation Cells are built in eight sizes from the No 25 to the No 1000 Parts of Flash Cells are interchangeable with the comparable size of standard Flotation Machine Pressure molded rubbercovered conical disk impellers are standard on all sizes due to the very coarse material handledFlash Flotation Cell 911 Metallurgist The flash flotation process involves the removal of as much of the well liberated valuable material from within the grinding circuit as possible to reduce the potential for overgrinding and consequent loss as slimes in a conventional flotation circuitThe role of a flash flotation circuit in an industrial

1 Froth Flotation – Fundamental Principles

1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry The particles with attached air bubbles are then carried to the surface and A series of laboratory and pilot flotation tests were conducted to find out the flotation performance of different ore types both with and without the Flash Flotation This data was used in modeling and simulating to find the optimal flow sheet for the highest Au and Cu recoveries with required Cu concentrate gradeModeling and Simulation of SkimAir® Flash Flotation Flotation Principles Air is dispersed in the suspension Hydrophobic particles attach to air bubbles and are collected in a froth phase while other hydrophilic particles remain in suspensionMineral Processing and Flotation Chemistry

Research Activities Related to Flotation Process

and activities on flotation, with main focus the contribution of physical chemistry to the process Surface Chemistry The flotation behaviour of methylated quartz particles of different size, but within the size range from 02 to 50 μm, and varying contact angle, has been probed in a mechanical flotation cell [15] Application of Continuous FlowFlash Chemistry to Scaleup Synthesis of 5Cyano2formylbenzoic Organic Process Research Development ( IF 3023) Pub Date : 00:00:00, DOI: Masaki Seto,Shinichi Masada,Hirotsugu Usutani,David G Cork,Koichiro Fukuda,Tetsuji KawamotoApplication of Continuous FlowFlash Chemistry to Scaleup Filtration is a process used to separate solids from liquids or gases using a filter medium that allows the fluid to pass through but not the solid The term "filtration" applies whether the filter is mechanical, biological, or physical The fluid that passes through the filter Filtration Definition and Processes (Chemistry)

(Important Topics) Chemistry: Froth Floatation Process

Important Topics Chemistry: Froth Floatation Process In some cases for example, sulphides ores of copper, zinc and lead concentration is brought by this method In this method advantage is taken of the referential wetting of the ore by an oilThe This article develops the flash flotation as an alternative method to gravitational separation and amalgamation in order to achieve a greater recovery of coarse native gold through selective hydrophobicity This method is directly applicated in the(PDF) Flash flotation of free coarse gold using Basic Principle of Froth Flotation Process The process of froth floatation starts with the Comminution process in which the surface area of the ore is increased First of all, the ores are crushed into very fine powder sized particles and mixed with water The mixture obtained is called SlurryFroth Flotation Process Detailed Explanation With

flotation separation process in chemistry

Flotation is a mineral separation process done in the water medium Inquire Now Filtration chemistry Britannica Filtration: Filtration, the process in which solid particles in a liquid or gaseous fluid are removed by the use of a filter medium that permits the fluid to pass Inquire Now and activities on flotation, with main focus the contribution of physical chemistry to the process Surface Chemistry The flotation behaviour of methylated quartz particles of different size, but within the size range from 02 to 50 μm, and varying contact angle, has been probed in a mechanical flotation cell [15]Research Activities Related to Flotation Process Application of Continuous FlowFlash Chemistry to Scaleup Synthesis of 5Cyano2formylbenzoic Organic Process Research Development ( IF 3023) Pub Date : 00:00:00, DOI: Masaki Seto,Shinichi Masada,Hirotsugu Usutani,David G Cork,Koichiro Fukuda,Tetsuji KawamotoApplication of Continuous FlowFlash Chemistry to Scaleup

Copper Flotation Department of Chemistry

Ore Concentration by Froth Flotation Remember that only 067% of the ore is copper The copper minerals and waste rock are separated at the mill using froth flotation The copper ore slurry from the grinding mills is mixed with milk of lime Flotation process (sometimes called flotation separation) is a method of separation widely used in the wastewater treatment and mineral processing industries fPRINCIPLES OF FLOTATION Mechanism of froth flotation are: Attachment of a specific mineral particle to air bubbles Being carried by the water in the floth Caught b/w particles in the frothFlotation Chemistry Materials The purpose of this study was the recovery of copper from the slag of Khatoonabad Flash Smelting Furnace (FSF) (Kerman Province, Iran) using the flotation method Flash smelting is an oxidizing process containing high grade copper matte The copper content of FSF slag is relatively high, and must be recovered before disposing of the slagRecovery of Copper from the Slag of Khatoonabad

Filtration Definition and Processes (Chemistry)

Filtration is typically an imperfect process Some fluid remains on the feed side of the filter or embedded in the filter media and some small solid particulates find their way through the filter As a chemistry and engineering technique, there is always Important Topics Chemistry: Froth Floatation Process In some cases for example, sulphides ores of copper, zinc and lead concentration is brought by this method In this method advantage is taken of the referential wetting of the ore by an oilThe (Important Topics) Chemistry: Froth Floatation Process This article develops the flash flotation as an alternative method to gravitational separation and amalgamation in order to achieve a greater recovery of coarse native gold through selective hydrophobicity This method is directly applicated in the(PDF) Flash flotation of free coarse gold using

Froth Flotation Process Detailed Explanation With

Basic Principle of Froth Flotation Process The process of froth floatation starts with the Comminution process in which the surface area of the ore is increased First of all, the ores are crushed into very fine powder sized particles and mixed with water The mixture obtained is called Slurry Thanks for contributing an answer to Chemistry Stack Exchange! Please be sure to answer the question Provide details and share your research! But avoid Asking for help, clarification, or responding to other answers Making statements based on opinion; back them up with references or personal experience Use MathJax to format equationsFroth floatation process Chemistry Stack Exchange and activities on flotation, with main focus the contribution of physical chemistry to the process Surface Chemistry The flotation behaviour of methylated quartz particles of different size, but within the size range from 02 to 50 μm, and varying contact angle, has been probed in a mechanical flotation cell [15]Research Activities Related to Flotation Process

flotation process Infoplease

flotation process, in mineral treatment and mining, process for concentrating the metalbearing mineral in an ore Crude ore is ground to a fine powder and mixed with water, frothing reagents, and collecting reagents When air is blown through the mixture, mineral particles cling to the bubbles, which rise to form a froth on the surface Ore Concentration by Froth Flotation Remember that only 067% of the ore is copper The copper minerals and waste rock are separated at the mill using froth flotation The copper ore slurry from the grinding mills is mixed with milk of lime Copper Flotation Department of Chemistry Flash calcination process of hydroxycarbonate precursor yielded cobalt catalyst of large surface area and high activity in ammonia synthesis reaction However, in comparison to conventional calcination method the resulting material was less crystallized and On the Effect of Flash Calcination Chemistry Europe

Recovery of Copper from the Slag of Khatoonabad

The purpose of this study was the recovery of copper from the slag of Khatoonabad Flash Smelting Furnace (FSF) (Kerman Province, Iran) using the flotation method Flash smelting is an oxidizing process containing high grade copper matte The copper content of FSF slag is relatively high, and must be recovered before disposing of the slag Filtration is typically an imperfect process Some fluid remains on the feed side of the filter or embedded in the filter media and some small solid particulates find their way through the filter As a chemistry and engineering technique, there is always Filtration Definition and Processes (Chemistry)