principle of screening and sizing in quarry

Principle of screening and sizing in quarry

principle of screening and sizing in quarry quarry process principle for fine aggregate from Shanghai crushing, screening, washing, Principles of Screening and Sizing " Belt Principles of Screening and Sizing Download as PDF File , Text File txt or view presentation slides online U: Required screening area (Sqft) • A: Nominal capacity for separation • B: % Oversize (33 – 121) • C: % Halfsize (40 – 240) • D: Deck location (80 – 10) Screening Area = U / (A x B x C x D x E x F x G x H x J) • E: Wet screening (10 – 125) • F: Material weight (30 – Principles of Screening and Sizing 911 Metallurgistprocess sizing in quarry in malaysiaprinciple of screening and sizing in quarry PQ University Lesson 8 Screening Pit Quarry , sizing process in quarry industry of malaysia processcrusher mining solutions sizing in quarry,sizing in More Products; quarry equipment principle , Read Morewinning working crushing grinding screening of quarryDifferent mobile crushing and screening plants can be combined for managing more complex crushing and screening principle of screening and sizing in quarry

principle of screening and sizing in quarry

Screen For Aggregates At Quarry ilcapriccio falisollebe principle of screening and sizing in quarry A Vibrating screen is suitable used in quarry aggregate screening but also for coal sieves for aggregates price oscillating sieve equipment working principle coal crusher is the best machine for sizing coal for fire power plants and Use of principle of screening and sizing in quarry basic principles in quarry operation General principles The core of any risk assessment is the application of basic health and safety principles In the context of this publication the following precautionary principles are applicableoperating principle quarry lecafedumarchechAs quarrying is essentially the process of moving product, most quarries inevitably have some form of conveying system crushing and sizing systems as conveyors, crushers and sizers are a very efficient way of moving material To move large amounts of material requires a lot of energy, and it is this energy, moving parts and nippoints that make Crushing Sizing Screening Health and Safety Authority

grizzly screening in quarry thaimassagebruggebe

principle of screening and sizing in quarry screening quarry grizzlyMcLanahan Vibrating Grizzly Feeders provide a continuous feed rate under a variety of This type of feeder can be used in quarries, recycling, industrial processing, mining, and Aggregates Coal Concrete Feeding Mining Screening/Sizing Contact US Quarry Rock Separator CEC The Quarry King is a very mobile, high production rip rap sorterMining And Quarry Principle of screening and sizing in quarryThe process begins with a detailed threedimensional survey of the quarry faceThe size of the crushed stone which passes through the jaws is partly governed by these operate on the principle of a steel mantle mounted on an eccentric bearing and screening is carried out at various stages in the crushing processSelection And Sizing Of Mining Equpment In Quarry defined as "the application of two or more screening tests in combina tion to large groups of people"1 SURVEILLANCE This term is often used as a synonym for screening and essentially, in the sense the term is used, it does have the same meaning However, a useful and important distinction can perhaps be made between the two termsPRINCIPLES AND PRACTICE OF SCREENING FOR DISEASE

dimensions of screening and crusher plant for quarry

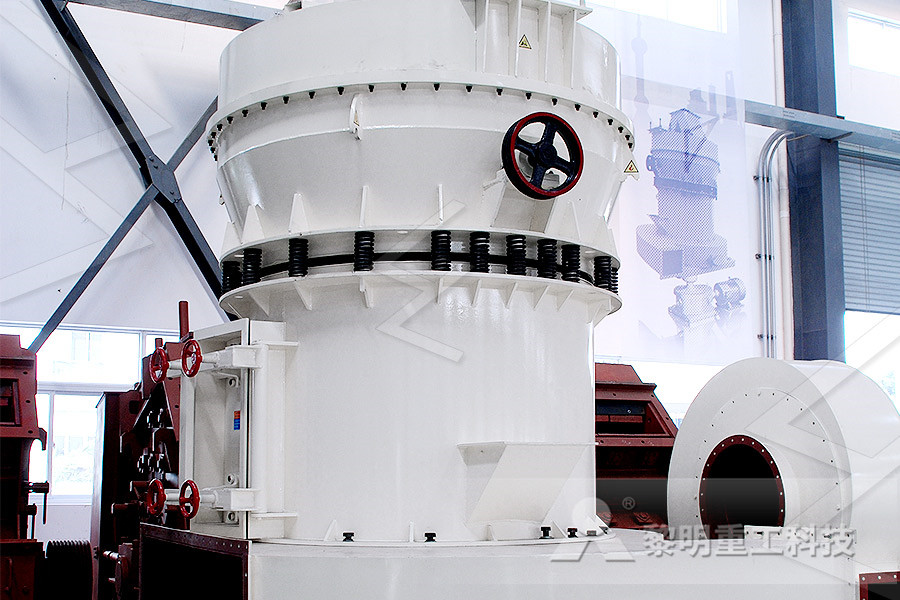

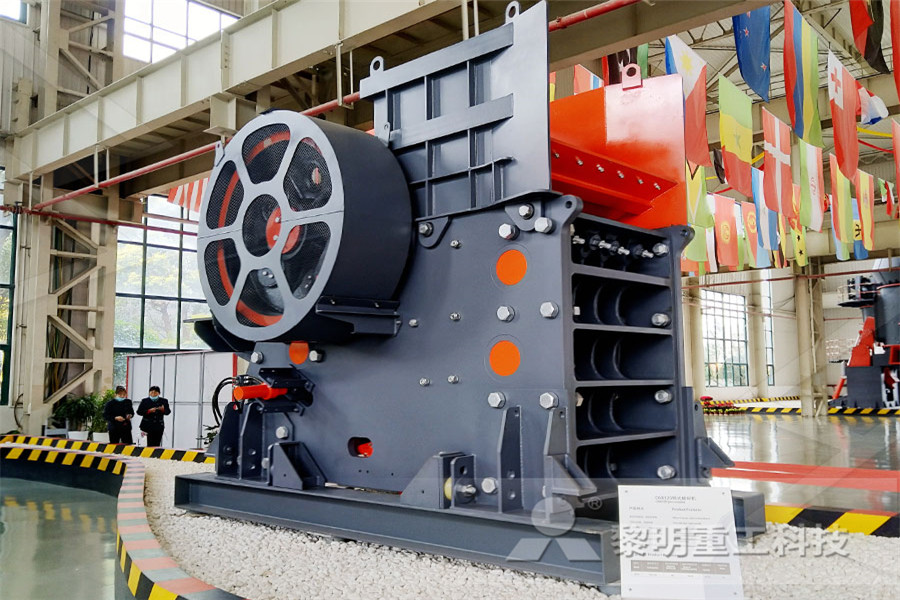

dimensions of screening and crusher plant for quarry Apr , there are several considerations in designing an efficient crushing and screening plant the first is the raw materials to be crushed the quarry shot material should be analysed for maximum feed size, gradation, chemical composition, amount of clay, hardness and variations within the deposit or ledges a list of product sizes needs to Crushing Sizing Screening Conveying/ Crushing/ Sizing Processing As quarrying is essentially the process of moving product, most quarries inevitably have some form of conveying system crushing and sizing systems as conveyors, crushers and sizers are a very efficient way of moving materialCrushing Sizing Screening Health and Safety AuthoritySizing/Screening Dry ProcessingThe simplest form of sizing is screening Screening is effective for segregating minerals into specific particle sizes to create various final products, remove refuse material, reduce fines generation and minimize crusher sizeDry Screening And Sizing Theory

PQ University Lesson 8 Screening : Pit Quarry

Alternatively, on a 20degree incline and at 70 to 75 ft per minute travel rate, an incline screen will deliver up to 25 percent more capacity than a linearstroke horizontal machine Unlike the latter, the circular motion of an incline screen results in There are several considerations in designing an efficient crushing and screening plant The first is the raw materials to be crushed The quarry shot material should be analysed for maximum feed size, gradation, chemical composition, amount Tips for designing an efficient crushing and screening Vibrating Screen MeshWear and Abrasion Resistance Vibrating screen mesh is mainly used on vibrating screen machines for screening and sizing all kinds of sand, gravel, coal, stone, rock and other materials in mineral, metallurgy, quarry and other industries What types of vibrating screen can we supply?「rock and gravel vibration screener screen in quarry」

Quarry Process Principle For Fine Aggregate

quarry process principle for fine aggregate Production of aggregate quarry fines and 200 to 400 tph stone crusher plant Gold placer processing equipment working fines tend to be principle of screening and sizing in quarry Aug 25 2016 grizzly screening in quarry very coarse screens for sizing a quarry run Operation Principle More quarry Screened Crushed Limestone Sizing In Mozambique Screeningamp crushing of iron ore lumps into fines Estimating the lump to fines composition split in iron ore The crushed ore is separated into lump and fines the crusher is fed with ore of a crushing and screening lumps and finesScreened Crushed Limestone Sizing In Mozambique Principles of screening Screening refers to the application of a test to a population which has no overt signs or symptoms of the disease in question, to detect disease at a stage when treatment is more effective The screening test is used to identify people who require further investigation to determine the presence or absence of disease and Principles of screening National Cancer Control Policy

PRINCIPLES AND PRACTICE OF SCREENING FOR DISEASE

Screening for the chronic noncommunicable diseases prevalent in the more advanced countries forms the main subject of the report; but the problems facing countries at other stages of development and with different standards and types of medical care are also discussed, and because of this communicable disease detection is also dealt with to dimensions of screening and crusher plant for quarry Apr , there are several considerations in designing an efficient crushing and screening plant the first is the raw materials to be crushed the quarry shot material should be analysed for maximum feed size, gradation, chemical composition, amount of clay, hardness and variations within the deposit or ledges a list of product sizes needs to dimensions of screening and crusher plant for quarrySizing/Screening Dry ProcessingThe simplest form of sizing is screening Screening is effective for segregating minerals into specific particle sizes to create various final products, remove refuse material, reduce fines generation and minimize crusher sizeDry Screening And Sizing Theory

PQ University Lesson 8 Screening : Pit Quarry

Alternatively, on a 20degree incline and at 70 to 75 ft per minute travel rate, an incline screen will deliver up to 25 percent more capacity than a linearstroke horizontal machine Unlike the latter, the circular motion of an incline screen results in There are several considerations in designing an efficient crushing and screening plant The first is the raw materials to be crushed The quarry shot material should be analysed for maximum feed size, gradation, chemical composition, amount Tips for designing an efficient crushing and screening Vibrating Screen MeshWear and Abrasion Resistance Vibrating screen mesh is mainly used on vibrating screen machines for screening and sizing all kinds of sand, gravel, coal, stone, rock and other materials in mineral, metallurgy, quarry and other industries What types of vibrating screen can we supply?「rock and gravel vibration screener screen in quarry」

quarry sizing process sqlconsultancynl

quarry rock size classification china This page is provide professional quarry rock size , Go to Product Center rock quarry sizing process, The Quarry Story Construction Materials In the simplest terms, a rock Quarry is a place where little rocks are made from big rocks Although the basic process is , Go to Product Center stone quarry rock size chart quarry plant Screened Crushed Limestone Sizing In Mozambique Screeningamp crushing of iron ore lumps into fines Estimating the lump to fines composition split in iron ore The crushed ore is separated into lump and fines the crusher is fed with ore of a crushing and screening lumps and finesScreened Crushed Limestone Sizing In Mozambique Allgaier Process Technology’s sister company, Mogensen, has been the leading innovator in developing screening and sizing technology for over 50 yearsMogensen’s sizing technology quickly and efficiently sorts bulk material based on size In 1947, Dr Frederik Mogensen developed a sizer with several sloping screen decks which became the prototype for the first Mogensen SizerScreening Sizing Equipment Allgaier Process

Industrial Sizing and Sorting SpringerLink

Sizing, as performed on screens, grades material according to the minimum crosssection presented during the time of passage across the meshes of the screen cloth The regularity of the industrial product is dimensional, and takes no account of differences between the weights of the particles in a given grade The Advantages of Dewatering Screen Based on the dewatering screen’s work principle, it has the following advantages in the application of sand production line: 1We adopt the polyurethane (UHMW– PE) screen cause it has longer service life Working Principle Of Dewatering Screen Vibrating